- Home

- News

- Machines

- Subcontracting

- Services

- R & D

- Laser Cheval

- Applications

For decoration , texturing, surface cleaning or traceability , LASER CHEVAL offers the appropriate solutions to subcontractors and manufacturers to reach high accuracy production, productivity and quality.

In comparison with traditional process, the advantages of laser technology are numerous :

The jeweler is precise, meticulous and patient.

He often works to the nearest millimeter on precious materials.

Any variation in measurement on a very small part can cause the distortion of the jewel. Therefore, the use of the laser on marking, cutting, engraving applications is highly explored by designers. That is why the use of the laser on marking, cutting, engraving applications is highly explored by designers.

Laser Cheval offers a wide range of machines for marking, welding and cutting applications.

The main advantage in the medical field : there is no contact between the tools and the laser-machines parts, but also the absence of ink which may be toxic.

Laser technology enables the user to have a very fine marking on small parts and a durability

The marking process is used for :

Laser welding is also used for the assembly of implant systems and for the production of surgical instruments. There are many advantages such as precision, accuracy, toughness, tightness, corrosion resistance, etc.

Our range of machines suit to the needs from this line of business (marking, welding, or cutting applications).

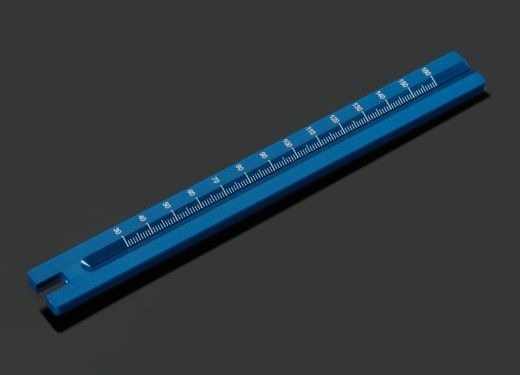

Laser technology is mainly used for traceability (serial numbers, bar codes, data matrix) and for graduation or even deburring of parts.