La soudure laser, un procédé parfait pour l’or

Laser Cheval develops laser machines capable of micro-welding gold parts for the watchmaking, jewelry and jewelry industries. The result is precise, discreet and long-lasting.

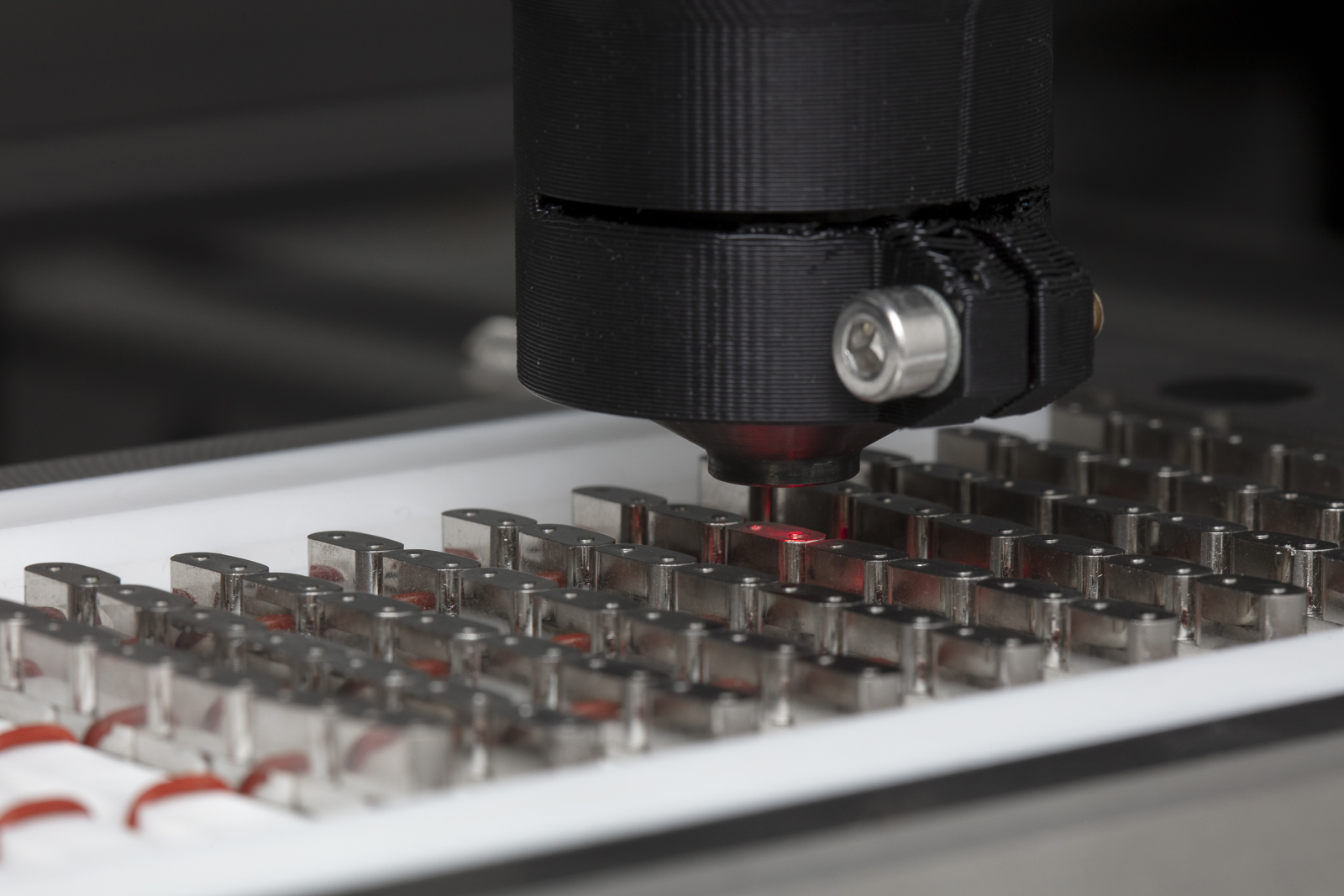

Microwelding of gold parts

The laser is a high-performance technical solution for soldering gold parts to achieve precise, discreet, aesthetic and long-lasting results. Laser Cheval, based in Marnay, Franche-Comté, has been specializing in the design of laser machines for 50 years, and has long been investing in the research and development of this technique in order to meet the ever-increasing demands of its customers in the high-end watchmaking, jewelry and jewelry sectors.

Laser gold soldering is an alternative to brazing, a traditional technique for assembling parts made of precious metals. Unlike laser soldering, brazing requires the use of a filler metal, which melts and seals the components together as it cools. Although brazing has proved its worth in the jewelry industry, it is less precise than laser welding, whose results are very convincing if the technique is well mastered.

Durability and aesthetics of micro-welding

There are two main criteria. The first is strength, i.e. obtaining a weld bead with sufficient penetration to meet the mechanical strength constraints imposed by the customer (with pull-out tests to back this up). The second is aesthetics. Once the parts have been welded, and after a finishing phase such as polishing or satin-finishing, they must be free of defects such as blowholes, marks or material heating.

Laser Cheval technicians pay close attention to these two parameters when calibrating a laser machine. They leave nothing to chance, and pay close attention to the indispensable test phases and the search for the right laser machine parameters, until they obtain a laser weld that meets the customer's expectations for the gold parts he needs to assemble. The result must meet the customer's specifications. In the end, mastery of laser technology ensures a consistently high level of quality. Precise adjustment means that the welding operation can be repeated with the same consistent result.

Controlled by LENS software

At Laser Cheval, each laser machine is controlled by in-house developed Lens software. This software has been specifically developed to support welding, and in particular pin welding. This digital environment can be customized according to the customer's final field of application. A tailor-made service that sets Laser Cheval apart from its competitors on the market. The fields of application for laser welding of gold parts are numerous. Currently, the machines manufactured by the Franche-Comté-based company are used in the watchmaking industry for the assembly of bracelets, pins, links and clasps.

The jewelry industry also uses laser welding for rivets, earrings and clasps. Laser welding can also be found in leather goods, for the manufacture of buckles, for example.